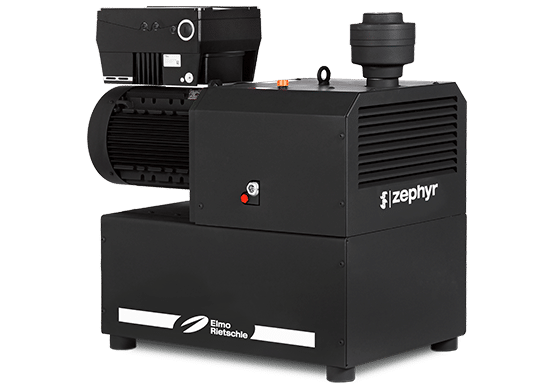

What is a Claw Vacuum Pump?

A claw vacuum pump is a very low maintenance tool and has integrated cooling air without the need for additional cooling mechanisms. The flow capacities range from 43 to 671 cm and the maximum ultimate vacuum capacity is up to 28.44″ HgV/32 PSIG. Internal compression allows for low pressure and low power motors, while the performance curve remains steady over its entire range making it suitable for a variety of applications.

Learn More

How Does a Claw Vacuum Pump Work?

Much like rotary vane and rotary lobe pumps, the C-Series claw compressors and vacuum pumps are based on a static compression system. But in contrast to rotary lobes, the compression happens internally by volume contraction. A claw pump’s two rotors turn in opposite directions in the compressor housing without contact. By using a precision gear set, they maintain very tight clearances. As the claw moves over the suction channel the gas is sucked into the compression chamber. As the rotors revolve, the gas moves from the suction side to the discharge side. During this rotation, the gas is compressed by the reduction of the volume between the rotors until the lower rotor uncovers the discharge channel. This “internal compression” leads to high differential pressures at efficiencies of more than 60 %. Afterward, the pre-compressed gas is discharged via the pressure connection. To remove the heat generated by the compression process, cooling air is sucked in between the compression housing and a silencing cover before it leaves the pump.

What Are the Benefits of a Claw Pump?

The claw vacuum pump is very efficient and compact, with no wear or friction. There are low life cycle costs associated with this technology, which reduces overall maintenance costs. It can also be used in conjunction with a frequency converter to increase efficiency, allowing the customer to adjust the vacuum to the desired capacity. Internal compression allows for low-end pressure while using the low power motors, all while keeping the desired efficiency rates (over 60%). The flat capacity curve, variable speeds at constant pressure, contactless operation (meaning no wear or friction), oil and exhaust-free compression air, and no water or oil inside the pumping chamber make the claw technology ideal for a wide array of applications.

What Are the Uses of a Claw Pump?

The claw technology is used in various applications including Medical, laboratory, graphic arts, and printing, industrial vacuum lifting, environmental engineering, pneumatic conveying, woodworking, and central vacuum systems. This design offers excellent service in pressure, vacuum, or a combination of both.

Cullum & Brown is here to guide you through every buying process. We look at the entire application and system to provide the best possible technology for our customer’s needs.