Compressed Air System Analysis

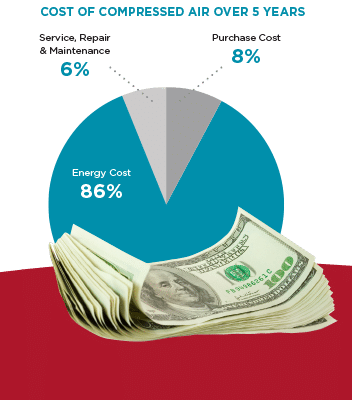

Compressed air is one of the most expensive utilities for a manufacturing plant. The annual energy cost to operate a compressed air system is usually tens of thousands of dollars, if not hundreds of thousands for many facilities. Compressed air is also, in many cases, required to keep the facility operating, which makes it necessary to have a reliable system that can produce high quality air.

By performing a compressed air audit, the existing system efficiency and reliability can be determined. The system can then be re-evaluated to determine what changes need to be made to meet compressed air best practices and provide optimum performance.

This can include the use of more efficient compressors, the installation of a compressor control system, additional storage, piping changes, the use of no-loss condensate drains, and improvements in the air treatment equipment.

Let's Talk Solutions

From turnkey equipment and system installs to 24/7 emergency service, we can help.

Contact Us