What is a Lubricated Rotary Screw Air Compressor?

A lubricated rotary screw air compressor (also known as an oil-flooded rotary screw air compressor) is a type of positive displacement air compressor. This means that air is trapped in a compression chamber and the space it occupies is mechanically reduced using intermeshing rotors causing a corresponding rise in pressure. The lubricant is introduced into the compression chamber during compression to serve three basic functions: lubrication of rotors and bearings, heat reduction due to the heat of compression, and it acts as a seal in the clearances between the meshing rotors.

Why Choose a Lubricated Rotary Screw Air Compressor?

Rotary Screw Air Compressor Versatility

Lubricated rotary screw air compressors are the most versatile compressor technology. With their wide variety of applications, they are great for medium to large-scale manufacturing where air demands are constant. They come in compact and complete packages to fit whatever a company’s needs are. In addition, rotary screw air compressors have broad ranges of capacity and pressure. The capacity control systems can effectively match any system demand allowing for even more flexibility for your compressed air needs.

Low-Cost and Efficient Air Compressor

Our rotary screw air compressor is great for anyone who is looking to save on costs. The lubricated rotary screw air compressor has a relatively low initial cost compared to other air compressors. The cost savings don’t stop there. The lubricated rotary screw air compressor has a long life, is energy efficient, and requires minimal maintenance. And when it does require maintenance, it is only routine and hassle-free maintenance. Finally, the vibration-free operation and lower noise levels provide even more convenience.

Buying a Lubricated Rotary Screw Air Compressor

If the rotary screw air compressor is right for your company, there are a few things to consider and plan for. One to think about is a company’s plans for future expansion to make sure compressor needs and capacity are properly accounted for. The right space and room are important to provide the air compressor with adequate cooling. Also, plan to conduct an air systems audit. This will help understand the exact demand to size the right compressor.

Isentropic Efficiency & Specific Power

The better the compressor design is at reducing the real-world losses, the higher the Isentropic Efficiency will be and the lower its Specific Power will be.

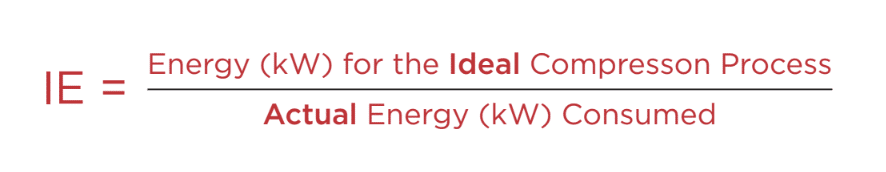

What is Isentropic Efficiency?

Isentropic efficiency is a ratio that indicates how the real energy consumption of an air compressor compares to that of an idealized compression process. The value is expressed as a percentage, and a compressor with a higher number is more efficient at converting electrical energy into compressed air potential energy than a compressor with a lower number.

What is Specific Power?

Specific Power, sometimes called specific energy, is an absolute energy-use metric, that provides energy consumption per unit of delivered capacity. It is the ratio of the actual work to the actual volume flow delivered by the gas compressor.

L-Series load/no load rotary screw fixed speed compressors from Gardner Denver feature more than just the latest base load compressor technology. They contain the cleanest, simplest, most intuitive machine layouts on the market.

L-Series load/no load rotary screw fixed speed compressors from Gardner Denver feature more than just the latest base load compressor technology. They contain the cleanest, simplest, most intuitive machine layouts on the market. LRS-Series variable speed rotary screw compressors from Gardner Denver feature more than just the latest, most efficient compressor technology. They contain the cleanest, simplest, most intuitive machine layouts on the market.

LRS-Series variable speed rotary screw compressors from Gardner Denver feature more than just the latest, most efficient compressor technology. They contain the cleanest, simplest, most intuitive machine layouts on the market. Featuring super-sized bearings and up to 40% larger air ends than the competition, the Electra Saver® II is not only bigger, it is better. The larger airends, running at slower speeds, maximize efficiency and reduce mechanical wear and tear, while the permanent alignment of the air end and motor ensures maximum coupling and bearing life.

Featuring super-sized bearings and up to 40% larger air ends than the competition, the Electra Saver® II is not only bigger, it is better. The larger airends, running at slower speeds, maximize efficiency and reduce mechanical wear and tear, while the permanent alignment of the air end and motor ensures maximum coupling and bearing life. The VST Series™ two-stage variable speed compressors from Gardner Denver not only deliver the standard 8–12% energy savings over a single-stage compressor, but will be the most efficient compressor you will ever purchase.

The VST Series™ two-stage variable speed compressors from Gardner Denver not only deliver the standard 8–12% energy savings over a single-stage compressor, but will be the most efficient compressor you will ever purchase. Over 40 years ago, Gardner Denver introduced the patented Turn Valve™ technology—the most efficient part load capacity control system in the industry. With infinite positions in an operating range of 40% to 100% capacity, compressor efficiency is maximized because the Turn Valve™ airend compresses only the volume of air required without affecting the built-in compression ratio at partial load conditions.

Over 40 years ago, Gardner Denver introduced the patented Turn Valve™ technology—the most efficient part load capacity control system in the industry. With infinite positions in an operating range of 40% to 100% capacity, compressor efficiency is maximized because the Turn Valve™ airend compresses only the volume of air required without affecting the built-in compression ratio at partial load conditions.