Why Should You Use an Air Knife System?

Unlike compressed air, which relies on greater compressor horsepower (and therefore greater costs), an air knife system paired with a regenerative blower can craft better results at a fraction of the price. Comparing both systems to dry a 36” length span of a conveyor on a 24/7 run cycle, a compressed air system would cost around $1,434 per week to operate. On the contrary, an air knife system and regenerative blower pairing would cost around $104 per week to operate.

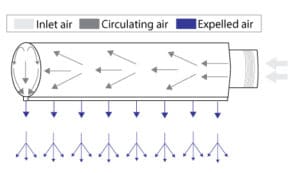

How Does an Air Knife System Work?

Air knife systems force pressurized air into a flow pattern that creates a high enough velocity to clean or remove debris from it without mechanical contact. The system’s pressurized air plenum with a uniform gap in which air exits in a laminar flow pattern. The exiting air velocity creates an impact air velocity directly onto the product surface to shear away moisture or particulates without mechanical contact. This impact air velocity can range from a gentle breeze to greater than 40,000 feet per minute.

What are the Advantages of an Air Knife System?

As previously covered, the primary benefit of air knife systems are the reduced costs when compared to compressed air systems. Other benefits of air knife systems include:

- Reduced energy consumption and utility bills

- Safe low-pressure air

- Dry, clean, oil-free air stream

- Filtered blower inlet to prevent particle contamination

- Increased production speeds and output for a quick payback

- Reduced sound levels when compared to compressed air nozzle or round tube design

Air Knife Applications

Air knife systems can provide great solutions in many setups and scenarios. Common uses are drying, debris removal, coating control, cleaning, and air loss prevention.

Air Knives for Drying Applications

- Bottles & cans

- Food products (fruits, vegetables, meat, fish, & poultry)

- Textiles, flooring, & carpeting

- Wire, cable, & batteries

- Coiled steel, metal, tile, & wood

- Hanging parts

- Extrusions, hose, plastics, & film

- Medicine vials

- Packaging, stamping, forgings, & machined parts

Air Knives for Belt Cleaning Applications

- Debris removal

- Sawdust removal

- Food topping or confectionery removal

- Liquid blow-off

Other Air Knife Applications

- Coating control of food & confectionery topping

- Reduce static

- Remove unwanted liquid

- Keep items from slipping through conveyor belt gaps

- Prevent hot and cold air loss

- Coating control of primers, glue, adhesives, & inks

- Crumb removal

- Pan cleaning